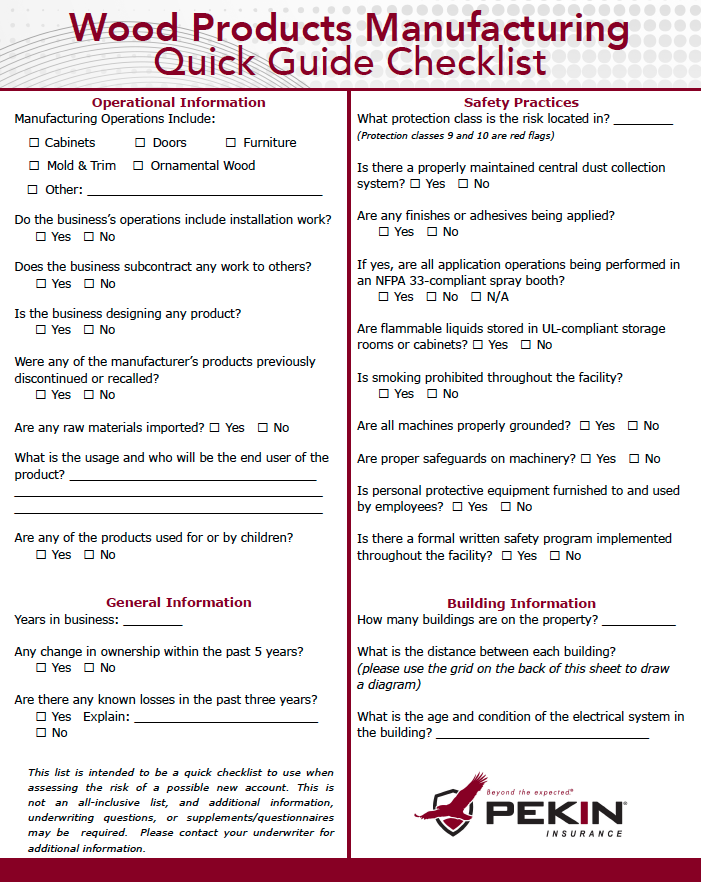

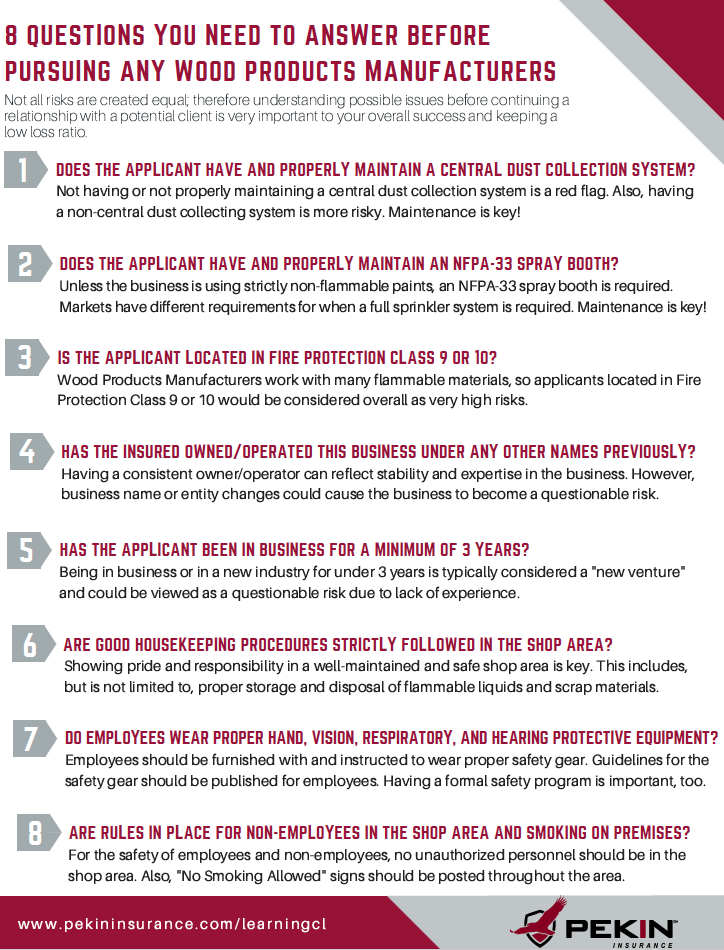

It is important to look at the operational factors of the business to help you determine whether it would be a good fit for your agency’s overall book of business. Certain types of wood products manufacturing can have a higher risk profile due to various hazards associated with their operations. Below are some examples to illustrate both “good” and “questionable” risks.

Spray Booths

Good Risk

- Proper use of an NFPA-33 booth when applying/spraying stains, varnishes, or adhesives is enforced at all times.

- There is only a one-day supply of flammable and combustible liquids stored in the spray booth and these liquids are only mixed in an approved area.

- There is an adequate ventilation system in the spray booth.

Questionable Risk

- The spray booth is NFPA-33 compliant, but the air filters need to be changed more often to ensure proper ventilation for the booth.

- A portable electric radio that is noncompliant with NFPA 70 (class I electrical) was plugged into an outlet within 20 feet of the spray booth.

- There is less than 18 inches of clearance between exhaust ducts and unprotected material.

Central Dust Collection System

Good Risk

- Use of properly functioning NFPA-EAW 664 dust collectors.

Questionable Risk

- Even with the central dust collecting system, very fine dust has begun to accumulate on the structural elements of the building, such as sills, beams, and rafters, which need to be examined and vacuumed regularly.

Storage of Chemicals and Solvents

Good Risk

- Flammable and combustible liquids are stored following the standards outlined in NFPA 30.

Questionable Risk

- Previously used rags were placed in self-closing cans during the day but were not removed to a safe location outside the building at the end of the working shift.

- A flammable liquids storage room had an air intake partially blocked by a storage container, which needed to be moved to ensure proper ventilation.

Safety

Good Risk

- Formalized safety procedures, a safety training program, and proper safety warnings related to hazardous equipment have been implemented and are enforced at all times.

Questionable Risk

- A customer was allowed in the work space to examine progress on the piece the shop was working on for the customer.

- Some “No Smoking” signs were obstructed from view in the flammable liquid storage and work areas where smoking is prohibited.

Spray booths, central dust collection systems, storage of chemicals and solvents, and safety procedures are only a few commonly occurring hazards that can elevate a business’s risk profile. Be sure to evaluate a business’s operations entirely as each business will deal with risk mitigation differently.

Note: The writings of Pekin Insurance are intended to be used for educational purposes only as well as to give you general information and an understanding of insurance. Pekin Insurance is not held to the accuracy or completeness of any information on this site or that is found by following any link on this site. Please refer to the policy, the specific coverage forms, and the endorsements for a detailed description of the coverages, limitations, and exclusions that apply. Each coverage scenario and policy are unique, so examples written by Pekin Insurance are not guaranteed.